单管软管泵应用范围:

石油工业中的钻井泥浆、原油输送及汽油、煤油等有机溶剂和燃料油的输送;水处理的淤泥浆,石灰浆输送;采矿、冶金行业,如金矿开采中的填充物料,黄金冶炼中矿浆输送;医药行业中药品料液的输送;食品行业中的油类物料及饮料输送;造纸行业的纸浆,硫磺浆输送;建筑行业的水泥砂浆输送;陶瓷行业的陶瓷釉浆输送;核废料、电解废渣、金属渣液、油漆、涂料等等液体物料的输送。

Drilling mud, crude oil transportation and transportation of organic solvents and fuel oils such as gasoline and kerosene in the petroleum industry; transportation of sludge and lime slurry for water treatment; mining and metallurgical industries, such as filling materials in gold mining, and pulp in gold smelting Transportation; transportation of pharmaceutical materials and liquids in the pharmaceutical industry; transportation of oil materials and beverages in the food industry; transportation of pulp and sulfur pulp in the paper industry; transportation of cement mortar in the construction industry; transportation of ceramic glaze in the ceramic industry; nuclear waste and electrolysis Transportation of liquid materials such as waste slag, metal slag liquid, paint, coating and so on.

豫信致诚机械设备有限公司 浙江宁波水渠机远销全国各地,本公司丰厚的 浙江宁波水渠机现货资源,严格的出入库核检程序,完善的配送体系,为满足新老客户的需求创造了良好的服务体系。

原则: 浙江宁波水渠机诚信为本、精诚合作、立足长远、永续经营。目标:优质的质量、优质的服务、优质的效益、优质的 浙江宁波水渠机品牌。宗旨: 浙江宁波水渠机用户的需要就是我们的责任、让用户放心就是我们的目标。

21世纪中国经济的快速发展,城市人口的大量增加,城市人口的日益扩大和人民生活水平的不断提高,城市生活垃圾产量也随之飞速增长,垃圾焚烧处理相对于其他的卫生填埋法、堆肥法比较而言,在土地污染、地下水资源污染、资源利用等方面具有 的优势,尤其是在人口高度密集、土地资源相对紧张、垃圾产量较大的大中城市和沿海经济发达地区,垃圾焚烧处理法得到大力推广,北京、深圳、上海、广州、宁波、苏州等经济发达城市已纷纷开始兴建垃圾焚烧电厂,日常生活的废弃物的充分利用来实现可持续发展的战略目标。我们在借鉴国外发达 在垃圾焚烧发电产业的成功经验的同时, 和地方政府也在政策和资金上大力支持发达地区利用焚烧法处理城市生活垃圾。

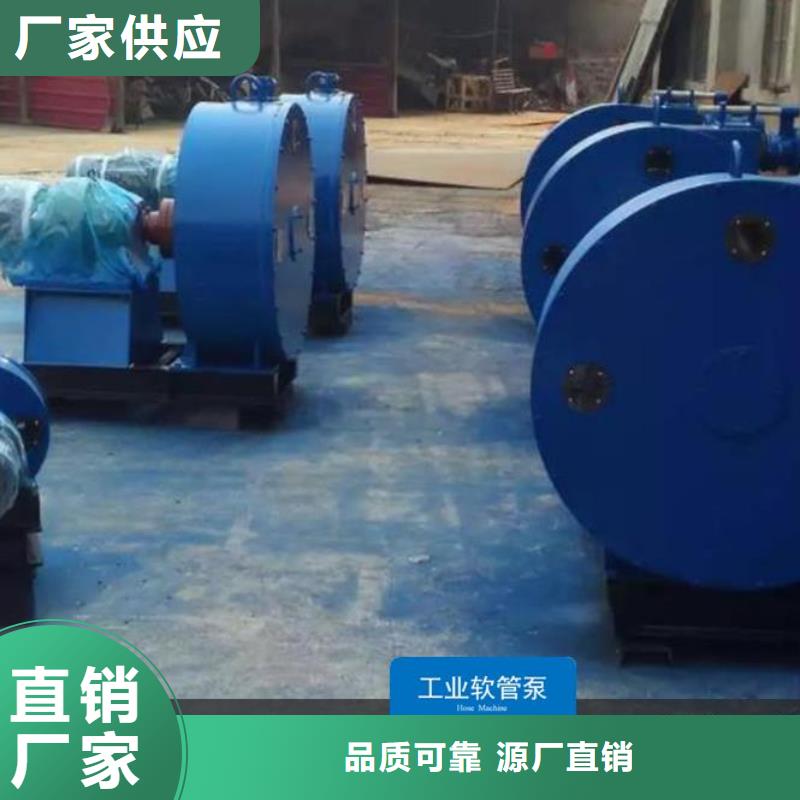

一根内壁光滑,强度可靠的特制橡胶软管安装在泵体内部,通过一对压辊沿着软管旋转挤压,这样的 旋转使得介质往一个方向输送而不会倒流,软管在输送介质之后,由被压扁软管的自身弹性和侧导轮的强制下,软管恢复原状,此时,软管内产生高真空将介质再次吸入管腔,然后介质在随之而来的压辊挤压下从软管内排出,如此周而复始,介质不断的被吸入和排出。目前产品使用温度为≤100℃。根据用户需要可以开发使用温度在120℃的软管泵软管产品。

Working principle of hose pump:

A special rubber hose with a smooth inner wall and reliable strength is installed inside the pump body. It is rotated and squeezed along the hose by a pair of pressure rollers. This rotation allows the medium to be transported in one direction without flowing back. After that, due to the elasticity of the flattened hose and the force of the side guide wheels, the hose returns to its original state. At this time, a high vacuum is generated in the hose to suck the medium into the lumen again, and then the medium is pressed by the subsequent pressure roller. It is discharged from the hose under the squeeze, and so on and on, the medium is continuously sucked in and discharged. The current product temperature is ≤100 ℃. According to user needs, we can develop hose pump hose products with a temperature of 120 ℃.

ag03.com

ag03.com